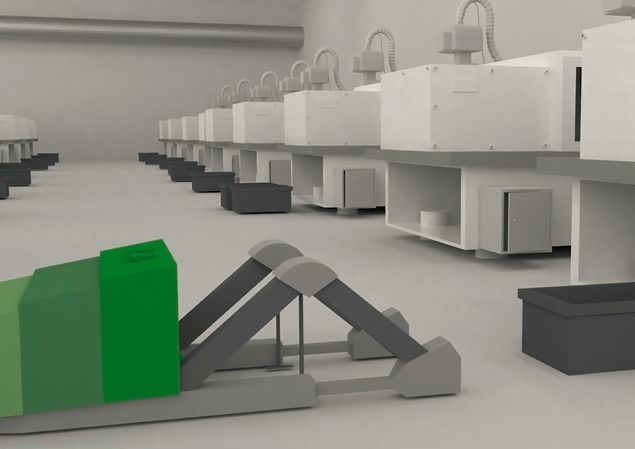

AGV shaped like "grasshopper", transported by "legs"!

Boston-powered "humanoid" handling robots, modeled after the R2-D2 in the "Star Wars" movie, developed the same delivery robot... and the AGV that looks like "grasshopper" introduced today. The above research and development design inspiration comes from the most authentic and colorful life.

The biggest highlight of the FLIP robot

1. More compact and more flexible

The width of the FLIP is 560mm, which is almost as narrow as the container it picks up. At the state of the art, comparable vehicles are significantly wider than FLIP robots. This is also the original intention of the designer. The compact design allows the robot to transfer positions in tight spaces, making it suitable for plant and internal logistics flexibility in Industry 4.0.

2. No operation center is required for robot operation

FLIP robots do not require a transfer station and can be unloaded and removed at any time (this is another step toward internal logistics without infrastructure).

3. High precision sensor

The FLIP robot is equipped with the latest sensor technology on the market – the innovative high-precision navigation sensor from Dutch startups. It ensures that the vehicle knows exactly where it is. The sensor measures ground characteristics while driving and provides motion and position data. Therefore, even in a changing environment without additional infrastructure, very high precision can be achieved.

How does the FLIP robot carry goods?

The FLIP robot is not only shaped like a "grasshopper", but also a moving object, like a grasshopper, that relies on two "legs" to move the cargo.

From the video, the robot needs to move to the side of the unit container with the cargo in the working scene, and reminds him to move the goods to the grasshopper's leg through the weight bearing. Then the FLIP robot picks up the container and stacks directly from the ground. Container, then drive towards the destination. The FLIP robot wraps the cargo with its own "legs" while driving, and it is necessary to step on the legs when lifting or moving the cargo. This action is similar to the "grasshopper" movement.

FLIP robots are currently designed for payloads of 60 kg. The prototype is equipped with a lithium iron phosphate battery (in principle, any other battery can be used). The design of the vehicle is up to 9 hours. Depending on the number of load picking operations per load and the weight of the load, this may be slightly different in practice.

It is understood that Fraunhofer Logistics and Logistics Research has applied for a patent for this product. At the same time, Fraunhofer IML is also looking for suitable partners to apply and successfully commercialize its products.

Reprinted from the network