Green intelligent design of logistics packaging

All logistics related packaging materials spending in the world will reach 271 billion US dollars by 2019.

Together with the total packaging expenditure for consumer packaging is about $820 billion. Among them, the United States accounts for nearly 24% of global logistics packaging demand, reaching US$76 billion; Asia accounts for nearly 46% of global transportation packaging demand, reaching US$145.7 billion; China accounts for about one-fifth of global packaging sales.

The green intelligent design of logistics packaging is the source of reducing logistics costs and improving the green indicator index.

First, the green intelligent design of logistics packaging protection packaging system

The intelligent design of logistics packaging should include two parts: protective packaging and packaging containers. There are 26 types of protection standards mentioned in the national standards, of which buffer packaging applications are the most common.

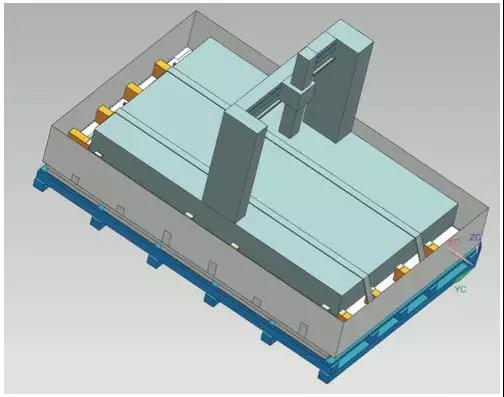

The following is an example of "Intelligent Packaging Design for CMM Buffer Packaging".

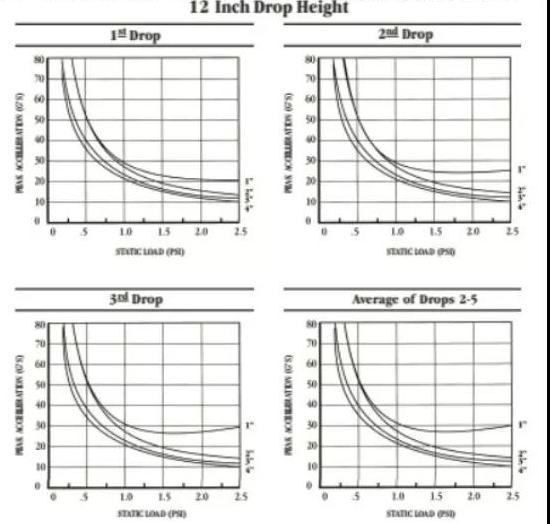

The buffer intelligent design module in the logistics packaging intelligent design software integrates the domestic and foreign related standards and literature introduction algorithms. The three-coordinate measuring machine with weight of W=10 tons is taken as an example to optimize the design. The cushioning cushion material is selected from Sealed Air's CelluPlank® 400 EPE, which has a drop height of 12 inches for different drop times and different buffer thicknesses t=1" to 4".

In the figure, the ordinate is the impact acceleration G (the unit is a multiple of the gravitational acceleration g), and the abscissa is the static stress σ of the cushion (in psi). According to ISTA3H, the design drop height of the CMM is taken as h=12 inches.

The big data shows that the dynamic shock absorbing performance of the closed-cell foamed plastic has an exponential function relationship represented by the formula (1) between the equivalent impact potential energy Y=hσ and the equivalent dynamic stress of the unit thickness X=Gσ/t:

Y=Aexp(BX) (1)

The coefficients A and B correspond to a specific type of closed-cell foamed plastic. For example, the data of the second to fifth drops obtained by the curve of Fig. 2 is (1), and the data fitting result is A=19.958, B=0.0711. In the case of a CMM, the brittle value is 40g and the drop height H=100 mm according to ISTA-3H, the thickness of the cushion is designed to be t=60 mm.

The "buffer packaging design" software can obtain the impact acceleration G=32.91, the optimal cushion area A=1103700 mm2, and the static stress σ=W/A=12.8869 psi. The impact acceleration when falling down is G=32.91g, which is slightly lower than the product brittleness value Gc=40; the compression static deformation of the cushion under this static stress is about 1.2mm, only 2% of the cushion thickness of 60mm. The effect on the buffer is within the expected error range.

Second, the intelligent design of packaging containers

The outer packaging container of logistics packaging mainly includes corrugated boxes, trays, wood packaging, plastic packaging, metal packaging and so on. The factors to be considered for selection are the weight, size, protection requirements, disposable or recirculating packaging, cost, etc. According to the requirements of the company, intelligent design modules for common packaging containers have been developed.

Third, the green evaluation of logistics packaging system

The green index assessment of logistics packaging system is mainly based on the life cycle assessment method to study the logistics packaging system, focusing on the carbon footprint of the whole process from “cradle to grave”. Firstly, the system boundary is determined, and the whole life cycle process of the logistics packaging system is elaborated. Secondly, relevant data is collected and calculated from the three aspects of raw material production and transportation, production and processing of the frame wooden box, and waste phase of raw materials.

For example, the life cycle assessment method is applied to the evaluation of green packaging, and a quantitative evaluation of a coordinate measuring machine frame wooden box is made through systematic and full life cycle analysis. Among them, the percentage of carbon emissions in raw material production and transportation is as high as 67%, the frame wooden box processing and transportation stage is 31%, and the raw material disposal stage is 2%.

Reprinted from the network