Learning the benefits and composition of intelligent three-dimensional storage

Intelligent three-dimensional storage generally refers to the use of several layers, dozens of layers or even tens of layers of shelf storage unit goods, with the corresponding intelligent material handling equipment and control system for the storage system of goods in and out of the warehouse, can make the warehouse floor high Rationalization, access automation, easy operation, intelligent management, and better realization of "smart manufacturing" and "smart storage" goals.

Intelligent stereo storage is generally composed of hardware devices and software systems. The hardware device is mainly composed of a storage unit, a material transfer unit and an auxiliary facility unit.

1. The storage unit

Mainly refers to the storage shelf, which is a steel structure or a reinforced concrete structure of a building or structure. The shelf is a standard size cargo space for storing cargo units.

The storage unit is provided with a corresponding identification tool such as an RFID tag, a two-dimensional code or a sensor to identify the cargo information and the storage environment in the storage unit. And through the WMS to achieve functions such as in-database management.

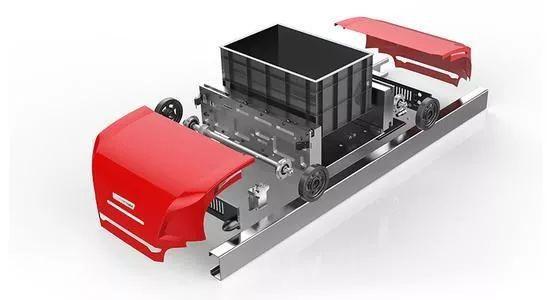

2. Material transfer unit

The function of the material transfer unit is to transfer the material between the location and the location, location and station. According to the usage scenario, it can be divided into intra-transport and intra-transport. The transfer within the library will be configured according to the specific conditions of the material storage, such as the physical properties of the material, the transit period, and the transport speed. Common in-transport equipments include stackers, shuttles, and the like.

Stacker

The main function of the stacker is to run back and forth in the roadway of the three-dimensional warehouse, store the goods at the entrance of the roadway into the cargo space of the shelves, or take out the goods in the cargo space and transport them to the roadway. Through the cooperation of the mechanical structure, the free movement of the space in the three-coordinate direction of the cargo bed in the roadway can be realized.

In the modern intelligent storage system, most of the stackers are controlled by automatic control devices, such as RFID reading and writing system, bar code sensing system to accurately locate the material information in each location, and then cooperate with the WMS system. Dispatching and commanding, accurate and efficient transfer of materials.

Shuttle

The shuttle is an intelligent transportation device that can be programmed to pick up, transport, place and other tasks, and can communicate with the WMS system, combined with RFID, barcode and other identification technologies to achieve automated operation. The shuttle operates in a reciprocating or loopback manner on a fixed track to transport the goods to a development location or to a docking device.

The shuttle is generally equipped with RFID and barcode recognition technology, which can accurately locate and identify the materials in the storage space. At the same time, the shuttle is equipped with an intelligent sensing system, an automatic deceleration system, which can remember the origin position and is in operation. The obstacles on the track are identified and automatically parked.

3. Auxiliary facility unit

Auxiliary facilities usually include fire-fighting facilities, lighting facilities, ventilation and heating facilities, power facilities, water supply and drainage facilities, and environmental protection facilities. Their functions are to ensure the normal operation of the warehouse hardware facilities and the storage environment of materials.

The software system is divided into WMS system and WCS system.

With the continuous development of science and technology, the production level of manufacturing and processing industry is constantly improving. "Intelligent manufacturing" has been paid more and more attention by enterprises. As an important part of intelligent manufacturing, intelligent three-dimensional storage will also be more and more enterprises. Introduced, applied and enhanced.

Reprinted from the network