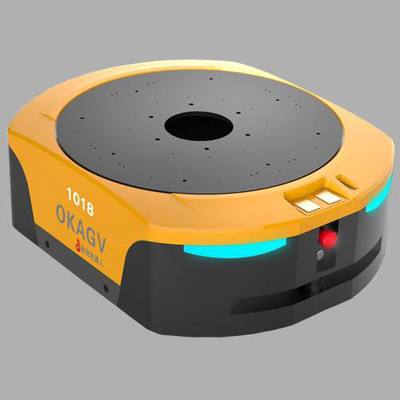

AGV handling robot

AGV: Automated Guided Vehicle (AGV), the most common applications such as: AGV handling robot or AGV trolley, the main function is concentrated in automatic logistics transfer, AGV handling robot is to automatically transport items to designated locations through special landmark navigation, the most common The guiding method is magnetic strip guiding and laser guiding; the most advanced expansion is currently guided by UHF RFID developed by Microcree Technology. The method of magnetic strip guiding is the common method and the lowest cost method, but the site setting has certain limitations and has certain influence on the venue decoration style; the laser guiding cost is the highest, and the site requirements are relatively high, so it is generally not used; the RFID guiding cost is moderate. The advantages are high guiding precision, convenient site setting to meet the most complicated site layout, and no impact on the overall decoration environment of the site. Secondly, the high security stability of RFID is also not available in magnetic strip navigation and laser navigation.

AGV performs material handling tasks efficiently, accurately and flexibly in logistics applications. And multiple AGVs can be combined to form a flexible logistics handling system.

High degree of automation, controlled by computer, electronic control equipment, magnetic induction SENSOR, laser reflector. When a certain part of the workshop needs auxiliary materials, the staff inputs relevant information to the computer terminal, and the computer terminal sends the information to the central control room, and the professional technician sends instructions to the computer. Under the cooperation of the electronic control equipment, this The order is finally accepted and executed by the AGV - the goods are delivered to the appropriate location.

Charging automation, when the power of the AGV car is about to run out, it will send a request command to the system, request charging (the general technician will set a value in advance), and automatically "queue" charging when the system allows it. In addition, the AGV car has a long battery life (more than 2 years) and can work for about 4 hours per 15 minutes of charging.

Improve logistics management. Thanks to the inherent intelligent control of the AGV system, the goods can be placed more orderly and the workshop can be more tidy.

For smaller site requirements, AGVs are much narrower than traditional forklifts. At the same time, for free-running AGVs, it is also possible to accurately load and unload cargo from conveyor belts and other mobile devices.

Reprinted from the network